Rotating Biological Contactors

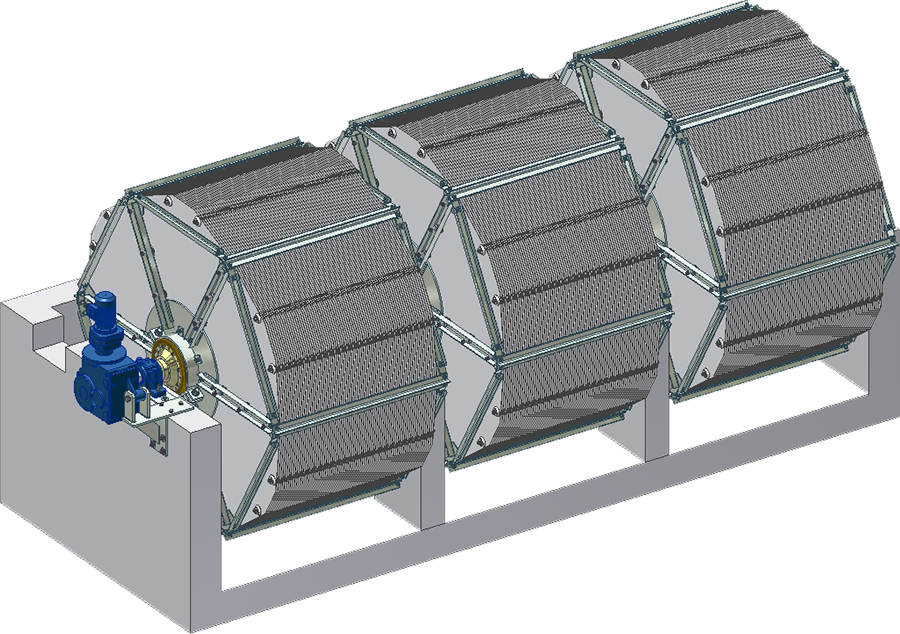

For more than 50 years, Mecana has been distributing rotating biological contactors (RBC) and a combination with pile cloth media filtration as compact solution worldwide. Mecana RBC are fixed-bed biofilm reactors with slowly rotating disks as carrier material through which the wastewater flows. The biofilm is alternately supplied with oxygen and wastewater by the rotating and partially submerged disks. This optimal supply for the carrier-fixed biomass enables efficient decomposition of organic ingredients as well as nitrification with an extremely low energy demand. Excess sludge is sedimented in a subsequent stage or, more advantageously, separated via PCMF, as common for compact plants. RBC plants are used for sizes ranging from 50 to 30,000 PE.

How RBC works

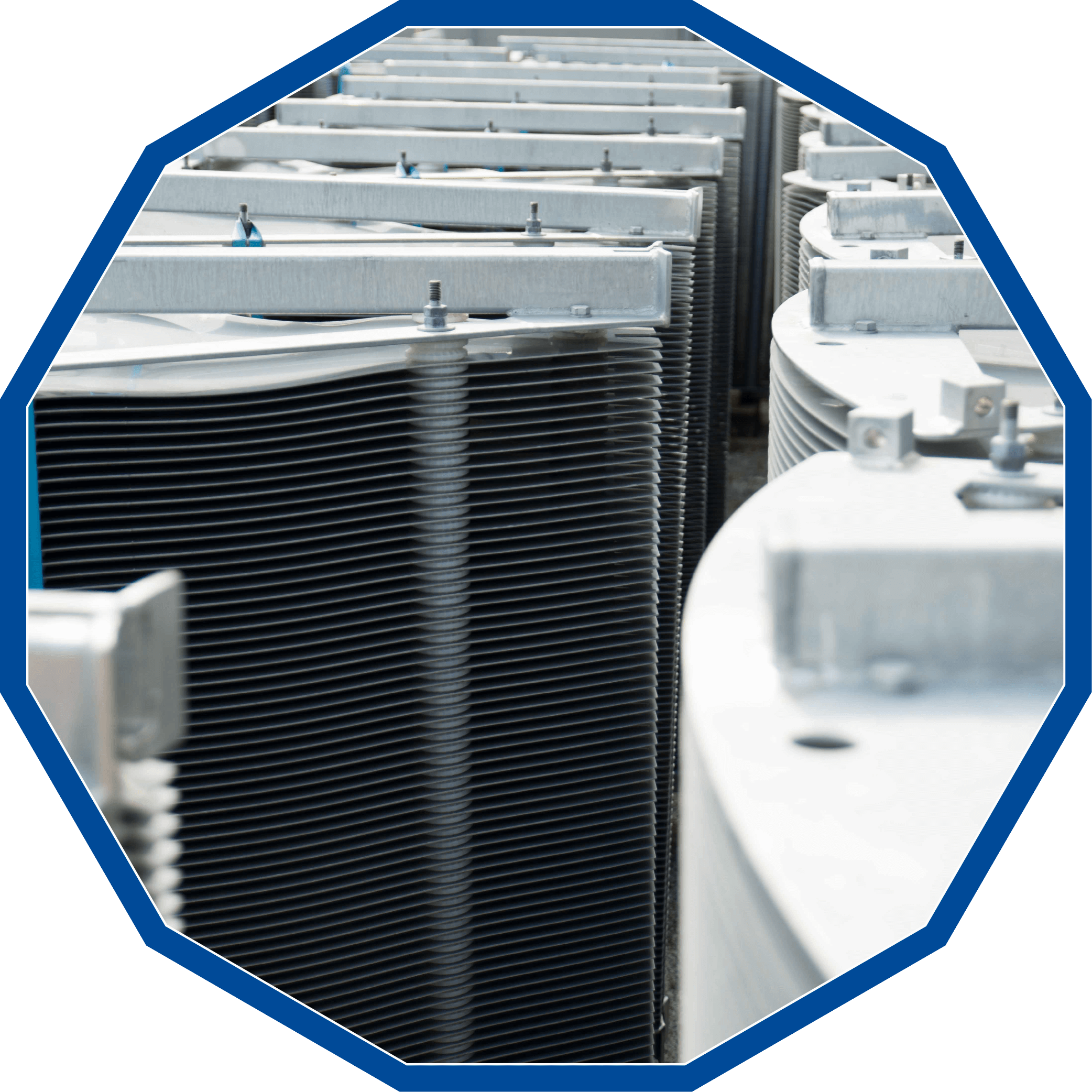

Mecana RBC consist of a central shaft on which approximately 2 mm thick disk segments are mounted with a clearly defined spacing. The individual disks, with a diameter between 2.0 and 3.6 m (RBC) or 1.2 and 2.0 m (MK), are assembled from 6 or 8 segments and are mainly made from recycled polypropylene. The system is installed in a basin made of steel or concrete. During operation, the disks are immersed in the wastewater with 40 to 60 % of their disk surface and are rotated by a drive on the central shaft. In this way, the biomass settled on the disks is alternately in contact with the required oxygen and the nutrient-rich wastewater. The pollutants contained in the wastewater are broken down by the biomass via biochemical processes.

Key Information

- No complex process control necessary, simple operation and handling

- Direct drive with low energy consumption

- Oxygen input without aeration system

- Low maintenance due to robust and durable technology

- Low space requirement

- Nitrification even at low temperatures

Applications

- Biological treatment of municipal and industrial wastewater for BOD removal and nitrification

- Landfill leachate

- Groundwater remediation