Water is future

Swiss Innovation

«Research and development - an investment in the future»

Innovation is closely linked to our philosophy and history. Since 1964, new and ground-breaking patents have been filed continuously. With the PCMF technology, Mecana has lastingly changed and shaped the filtration market. Our engineers plan new plants, create process concepts and sustainably develop the technologies based on current and future needs. Accordingly, new application possibilities for solids separation in the field of trace substance removal, water reuse or pre-filtration for surface and drinking water treatment have been developed.

The innovation team is constantly looking for better and more sustainable solutions for (waste) water treatment and works in close partnership with recognised institutions, universities and utilities worldwide. Together with Aqua-Aerobic Systems, Inc., Mecana oversees the world's largest research center on PCMF technology.

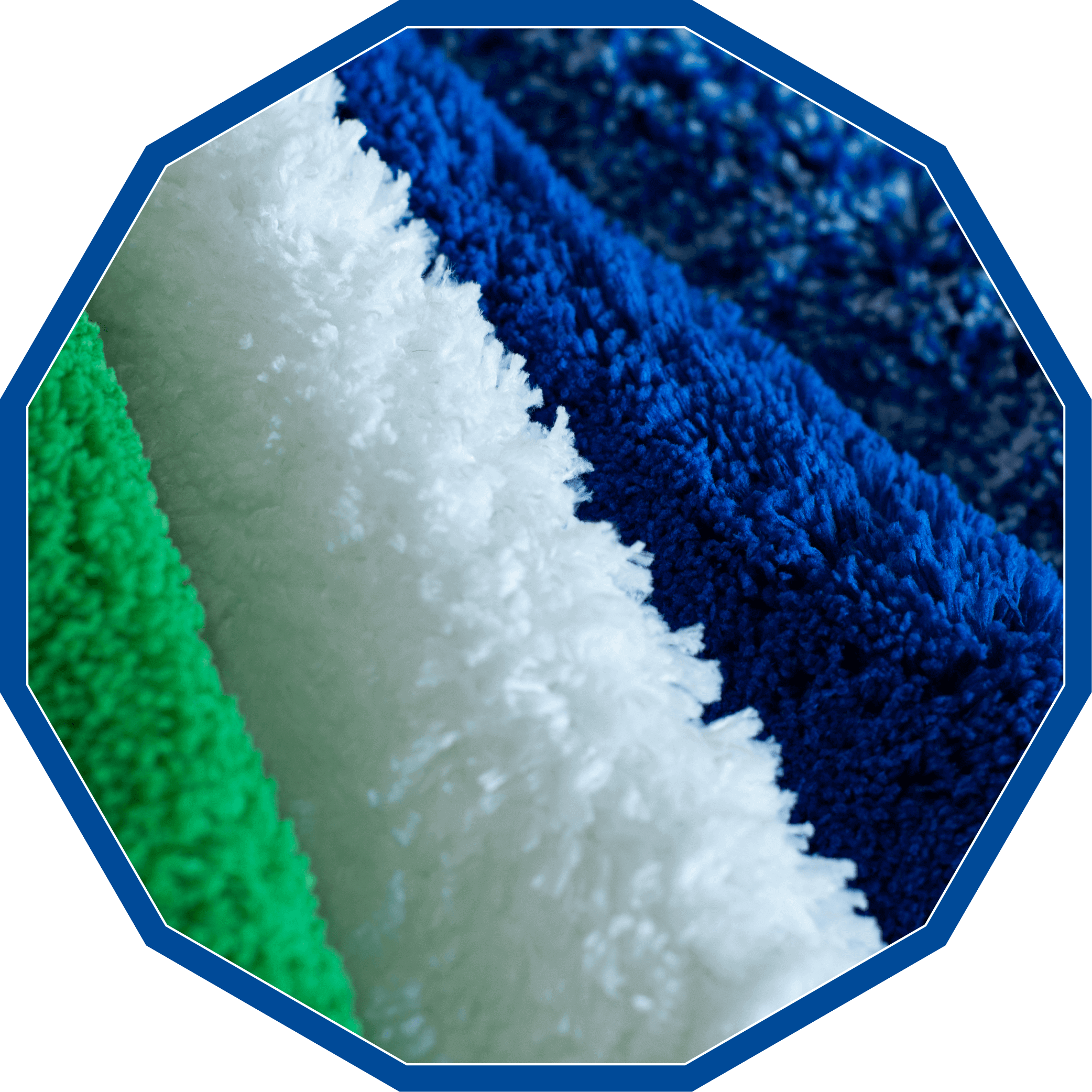

Pile Cloth Media Development

The filter medium is the heart of PCMF technology. The Pile Cloth Media development began in 1994 and resulted in today's OptiFiber® as an engineered filter media. OptiFiber® pile cloths are designed to balance maximised solids removal, efficient backwash performance, minimal amount of backwash water and long-term stability. From the development to the introduction of a new pile cloth, up to 10 design variants are tested over months to years for solids and particle retention, creep strength, chemical and temperature resistance. Proof of creep resistance (constant filter performance and integrity of the filter medium) is provided by means of an endurance test (> 500,000 cleaning cycles) for each type of pile cloth in a technical facility under real conditions. Quality assurance is achieved through strict controls (on raw and production materials, test assembly, final inspection, retention samples and endurance test) and serial numbers on each filter bag to ensure traceability. Hundreds of pile fabrics were tested as part of this continuous development process. Only five of these options survived the rigorous testing processes.

Since 2011, Mecana has operated a research and development center together with Aqua-Aerobic Systems, Inc. The facility is used for applied research and demonstration of new products. The center is integral to the development and testing of OptiFiber® pile cloths for future commercialisation and application, both domestically and internationally.

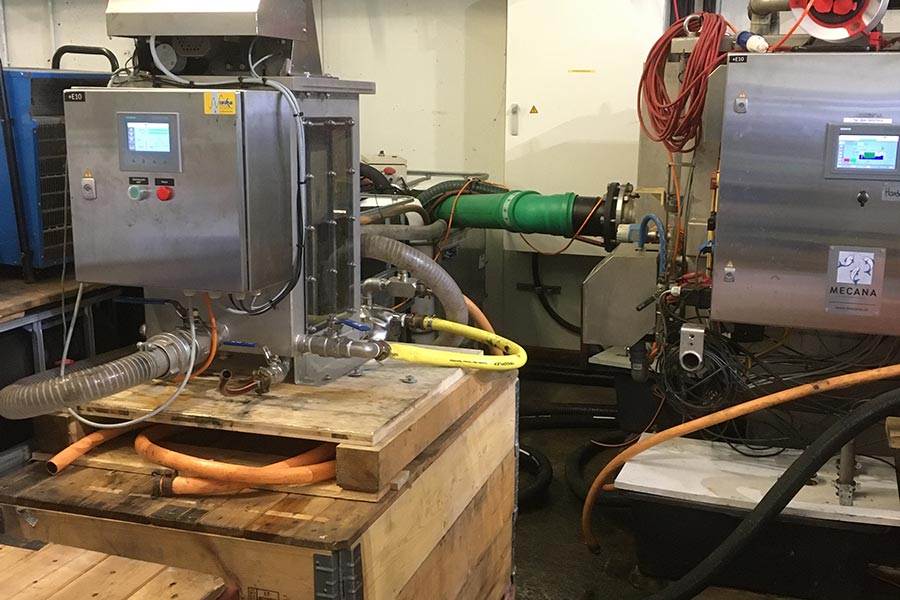

Pilot plants

Testing creates trust. Mecana test facilities offer an independent and neutral evaluation of PCMF technology. Pilot testing provides rapid feedback on the performance of the OptiFiber® family for multiple and even unproven applications. Upon customer request, Mecana guides the pilot testing period and provides a comprehensive analysis service. This ensures that the experience gained from testing is also integrated into the plant design and subsequent implementation. Mecana has a fleet of pilot plants, including:

- Minifilter

- Mecana Drum Filter (MTF)

- Mecana Disk Filter (MSF)

- Mecana Pressure Drum Filter (MDF)

In addition, the pilot plants can also be used as part of a rental program to meet customer-specific needs over an extended period of time. In addition, Mecana operates a laboratory for pile cloth media specific tests and the measurement of legally prescribed (waste) water parameters, which is used for the operational monitoring and control of the compact plants as well as pilot plants.

Mecana®365

Gaining and advancing knowledge through a sustainable digitalisation strategy.

Industry 4.0, the creation of digital solutions is a challenge for the (waste) water industry. With Mecana® 365, we offer our customers, partners and suppliers not only a comprehensive service and 24/7 accessibility, but also the products for digital transformation and cloud-based solutions. Besides water as essential raw material, data is the digital raw material of the future. With the Mecana®Cloud, raw data is transformed into real-time digital information and delivered in a customised way. Our Mecana®IIoT (Industrial Internet of Things) creates the networking of plant-specific sensors and instruments with Mecana technology components. Thus, not only can operating costs be reduced by identifying optimisation potential, but the pulse of the Mecana technologies can also be monitored. This enables stable, continuous and sustainable plant operation.

With the Mecana®Analysebox, we also offer a tool for short-term or continuous operational monitoring and optimisation of PCMF technology. Whether as a rental application or permanent solution, the analyse box provides 24/7 real-time information, data storage and data evaluation by means of machine learning tools. Data storage on servers localised in Germany is subject to the strict European data protection directive.

Our test and rental facilities have already had the Mecana®Cloud since 2020, which creates complete technology transparency for our customers. In the future, Mecana will offer customised cloud solutions to the technologies and thus contribute to the digital solutions of tomorrow.

Contact us

Copyright © 2024, Mecana AG

All designations with the ® symbol are registered trademarks of Mecana AG or Aqua Aerobic Systems Inc. They are protected in Switzerland, the European Union and other countries.